Smart Klaus

THE Smart Klaus – Assembly Assistant & Quality Control

Embrace machine vision technology to enhance both the quality and productivity of your production line. By implementing advanced vision systems, you can achieve unparalleled accuracy and efficiency, driving continuous improvement in your manufacturing processes.

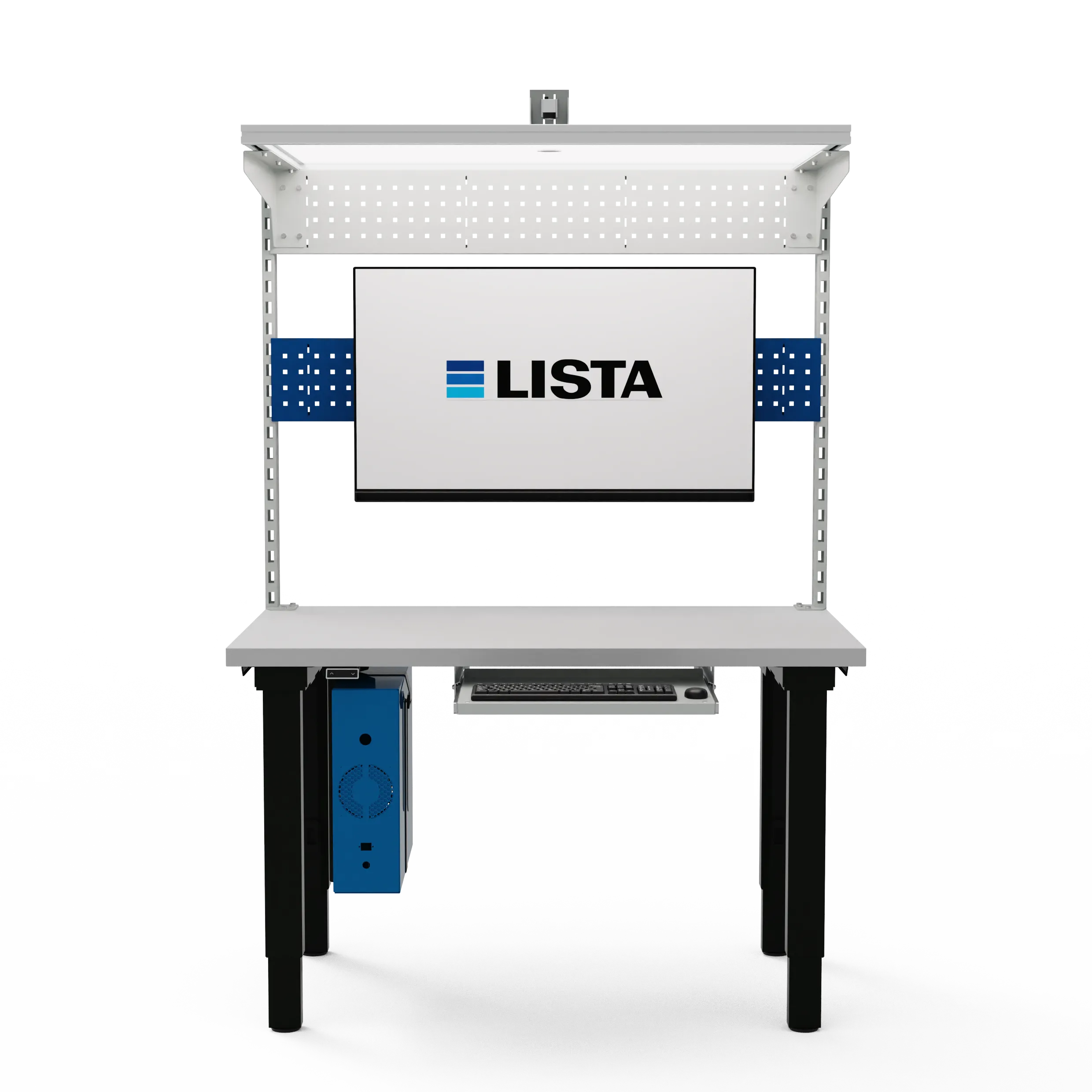

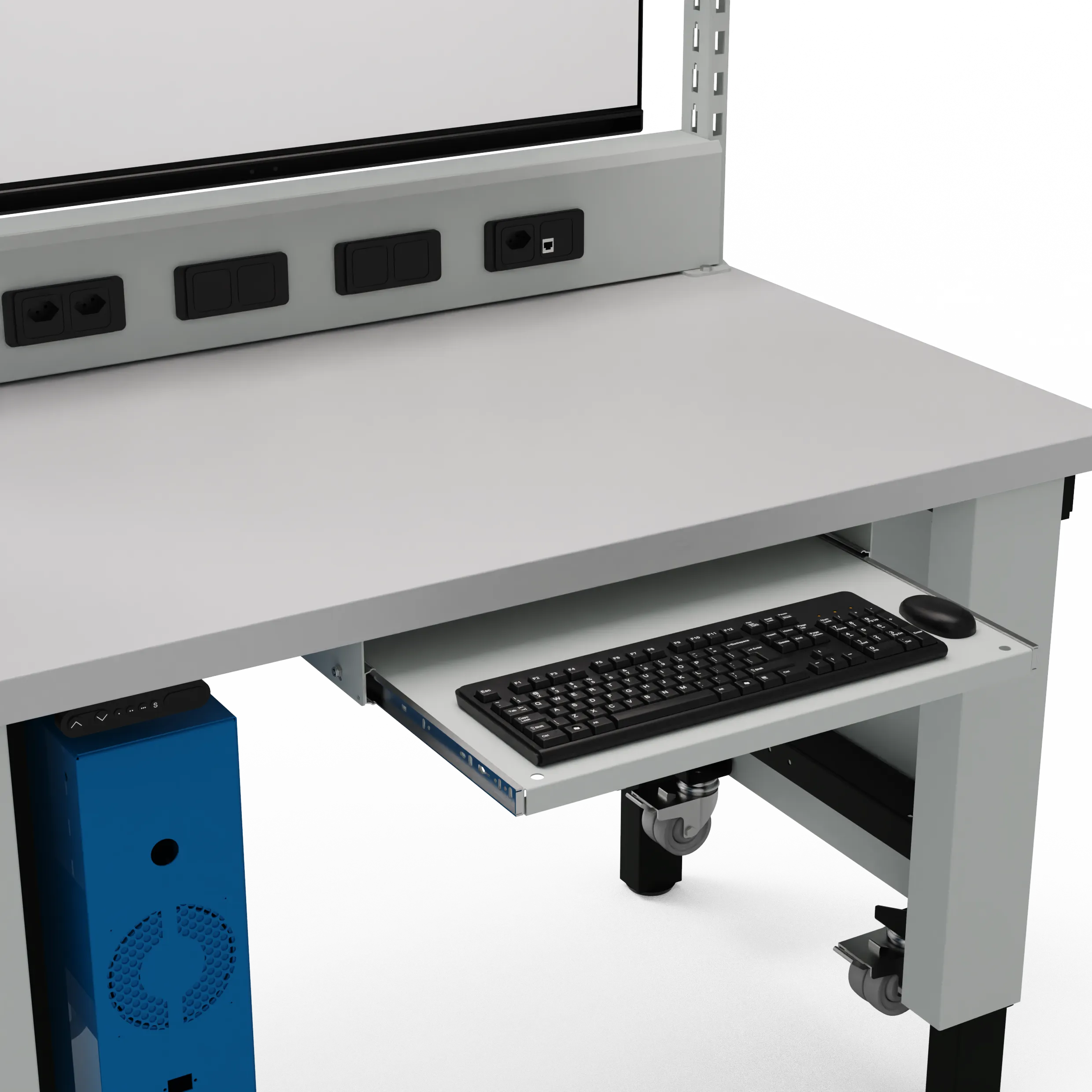

Workstation from Lista , software from Optimum and provision of Automation.ch

The “Smart Klaus” complements Lista’s individually configurable workplace and brings your work processes together to the next level. The software can take on various tasks. Instructions can be provided using images and sound and light projections can be played. Quality assurance is directly integrated into the program recognizes, checks and saves individual work steps. Reading QR or OCR codes, e.g. for The automated goods receipt process is also one of the many possible uses of “Smart Claus”. External tools, measuring devices and systems can be easily integrated. Position multiple cameras from different angles. With our 100mm lenses you can… Field of view of 25mm x 35mm achieves a detection accuracy of 0.01mm. A 12mm lens allows for a Field of view of 1.2m x 0.86m with an accuracy of 1.6mm. Once used, “Smart Klaus” becomes the indispensable team member in your company.

0 PPM Possible

Unbeatable All-Round Service

Wide range of possible uses

To know digitized

High Flexibility Through Extensions

The system guides employees through entire work processes with digital instructions, eliminating the need for time-consuming and costly corrective measures. This guidance ensures that tasks are performed consistently and efficiently, leading to higher productivity levels. Furthermore, the digitalization of work processes enables automation and optimization, resulting in increased efficiency and profitability. By streamlining operations and reducing manual intervention, companies can achieve significant cost savings and maintain a competitive edge in the market.

Consistently High-Quality Results

Videos

Are you interested in our product?

We Are Here To Help!

Contact Us